VJ Technologies wants to develop a range of X-ray scanning machines based on computed tomography (CT) for industrial applications. CT technology is considered as the most advanced inspection technique available in the non-destructive industry. CT scans provide highly detailed images of internal structures, aiding in accurate inspection, R&D support and 3D generated CAD geometry. To implement this technique, it is required to develop scanning machines with a high level of precision and repeatability. Next to that, all these systems need an identical look and feel, that reflects the first-class standard that VJ Technology wants to achieve.

The new range of X-ray scanning machines varies in size from 1200 to 4300mm in length and 600 to 3200 in height. The ‘Veda Mini’ is the first system to be introduced.

Client

Year

2024

Services

- Brand design language

- Product Design

- Engineering

- Prototyping

- Technical package

Safety and complexity

The portfolio of VJ Technologies holds several systems, from small systems (tabletop) to large machines up to 4 meters of height. For safety reasons, some machines are placed in X-ray proved rooms. Other systems come with a lead shielded cabinet to prevent leaking of X-ray radiation. The integration of this protective shield can be very challenging, because of the extra mass added and lack of space.

Engineering in a world of microns

The VJ ‘Veda’ scanning machines operate within the field of microns. The embedded advanced equipment linked to the precise engineered construction guarantees a highly detailed 3D image. Accordingly, DE Design developed several mechanical systems that meet these tight tolerances and demanding specifications. For example, the mounting instructions of the linear guide rails describes a flatness of 50 microns and a parallelism of 100 microns over a length of 2500mm

Next to the preciseness, we focused for the larger machines on the stiffness of the base-frame, columns and brackets. The brackets hold the source and detector that can move from position. Moving these parts might not result in any deformation that affects the quality of the image.

Prototyping and refining the system

For the smallest CT scanner, the Veda Mini, we built a mechanical working prototype to test the current construction and refine when needed. We focused on the overall rigidity and the transmission system that drives the loading stage and U-shaped door.

Next to the technical aspects, we build an aesthetic pleasing showpiece, ready to be presented at potential customers.

Prototyping and refining the system

For the smallest CT scanner, the Veda Mini, we built a mechanical working prototype to test the current construction and refine when needed. We focused on the overall rigidity and the transmission system that drives the loading stage and U-shaped door.

Next to the technical aspects, we build an aesthetic pleasing showpiece, ready to be presented at potential customers.

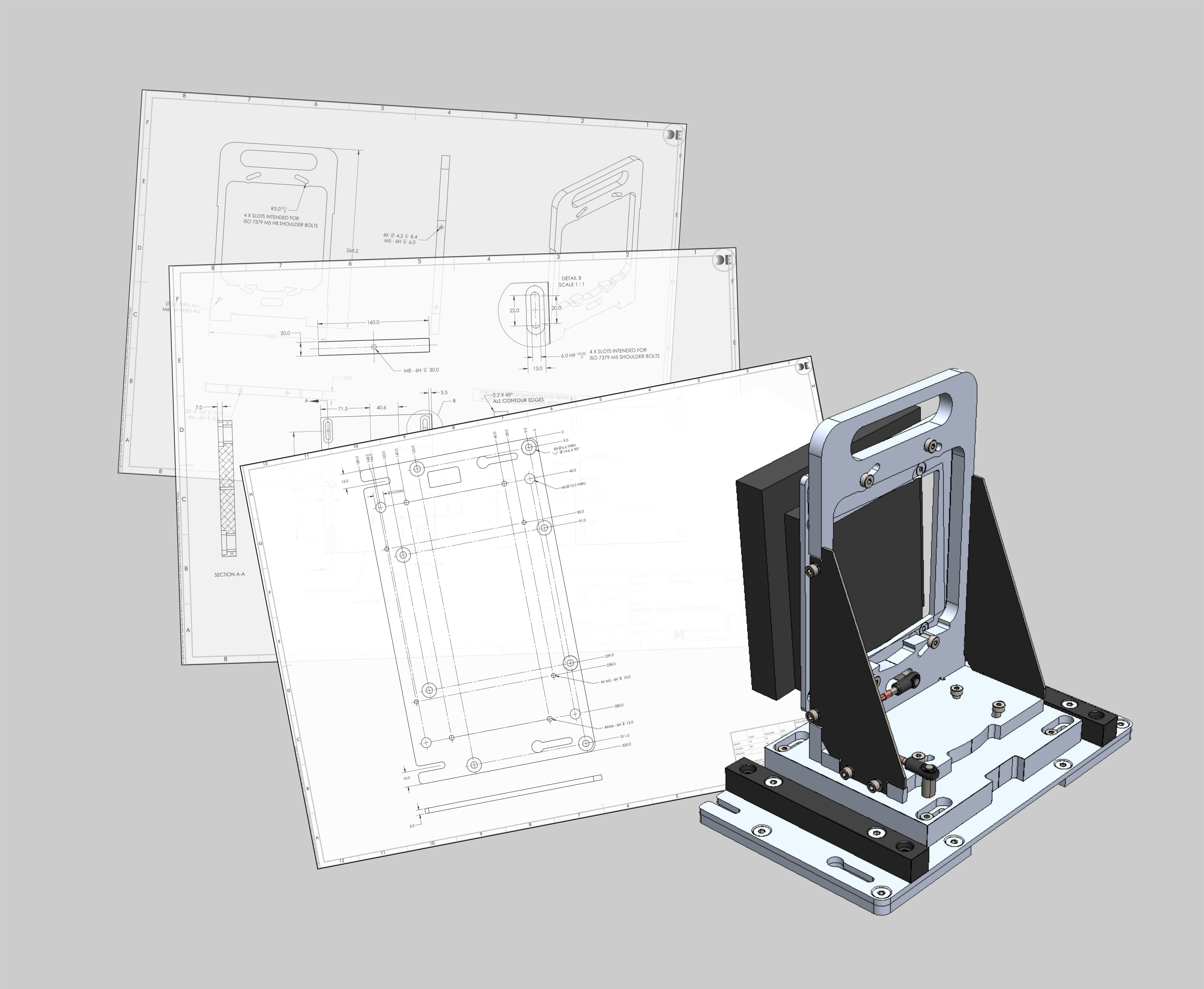

Technical package

For all CT systems we provided a technical package that contains the mechanical drive components, CMF, BOM and 2D drawings for manufacturing and assembly. The drawings define the tight tolerances in relation to the complete system.

Overall impression